CMM programming is one of the many precision engineering capabilities we have at M-CNC. Read on for a closer look at what CMM programming is and how it is used in manufacturing.

What is CMM programming?

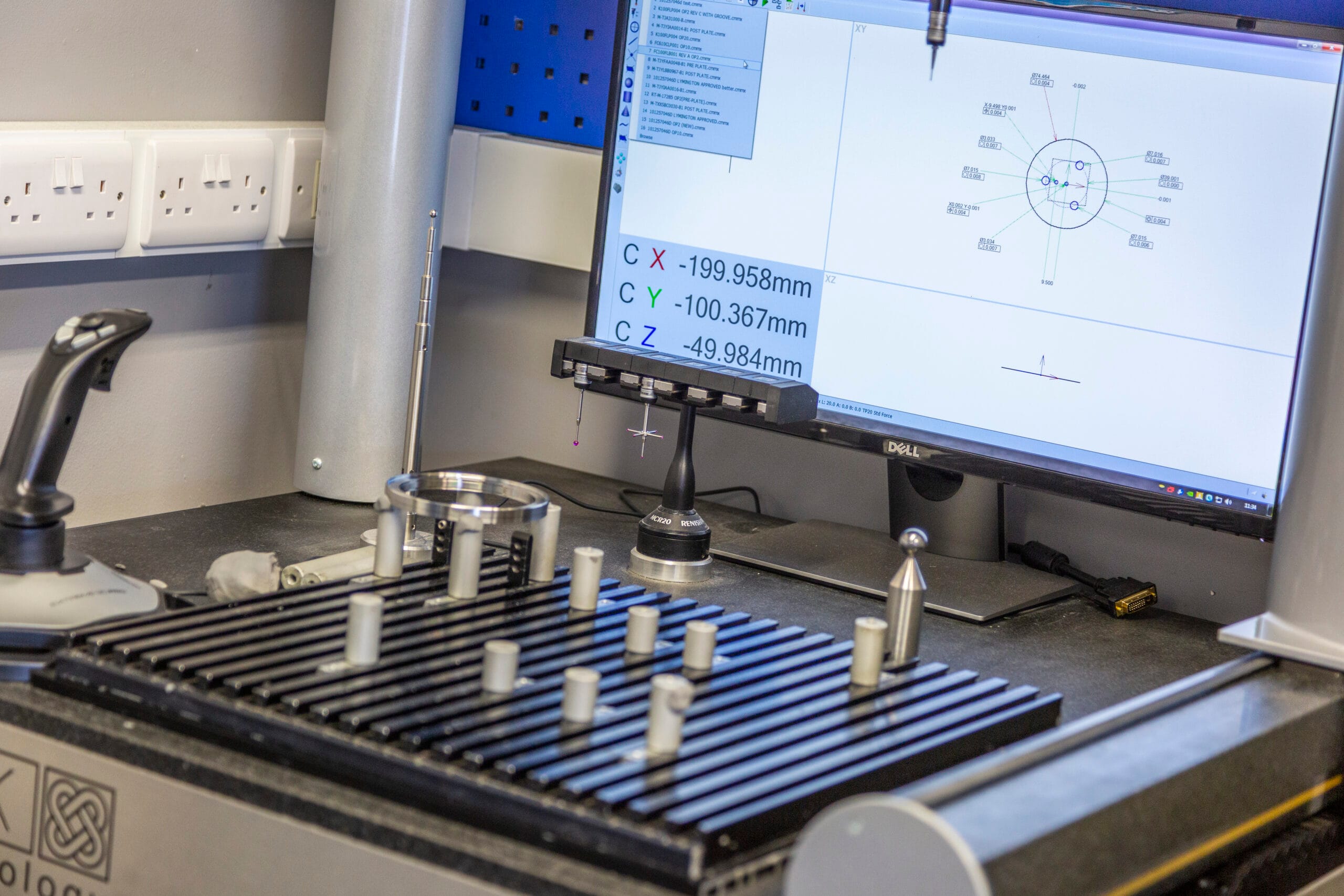

CMM stands for Coordinate Measuring Machine. A CMM is a machine that precisely measures the physical geometry of manufactured parts. Using CMM measurement and programming, we can deliver high quality parts that are accurate down to the last micron.

What is CMM programming used for?

Most often, CMMs are used to test a part and check that it meets the intent of the original design as closely as possible. CMMs are part of our quality control process, able to measure the geometry of physical objects to an extremely high degree of accuracy.

CMM programming tests a manufactured component to ensure it has no quality issues or unexpected deviations from the original design. This testing is done using laser shaft measuring equipment and shadowgraph measuring, all employed by our coordinate measuring machines.

Which sectors use CMM programming?

At M-CNC, we are able to meet the demands of highly prestigious sectors – including the likes of aerospace, security and defence, and motorsport. These industries demand absolute precision and quality from the parts we manufacture for them.

Our state-of-the-art Aberlink CMMs are housed in temperature-controlled facilities and integrated with inspection software. Our clients receive precision engineered components with the confidence that every part has been tested and found to be within the accepted tolerance levels. Every part is supplied with full quality inspection reports that attest to this quality.

What are the advantages of CMM programming?

1. High precision

Compared to manual part inspections performed with conventional measuring instruments – height gauges, micrometres, etc. – coordinate measuring machines offer a degree of accuracy these methods simply cannot match. CMMs are able to measure every angle of very complex parts with ease to a level of precision manual measuring cannot achieve.

2. Manufacturing efficiency

Our coordinate measuring machines can measure different points of a part many times over, increasing workflow efficiency. CMMs use a measuring probe that moves automatically along preprogrammed paths, removing the need for manual manipulation. This reduces the risk of human error causing a quality issue to be missed.

CMMs also deliver supremely accurate measurements very quickly, greatly increasing the efficiency of the manufacturing and quality control processes.

3. CAD integration

We achieve precise machining of parts by employing CAD/CAM CNC programming. Our CMMs integrate seamlessly with our CAD (computer-aided design) software to make sure every part we manufacture meets the demands of the original design.

CAD software integration also further ensures that the measurements our CMMs take of each part are incredibly accurate.

4. Quality control

Once an inspection of a part is complete, our CMMs produce the necessary quality control documentation. This is an essential part of the quality control process, and provides our clients with a traceable record of every part we create for them.